Cutting-edge Approaches in Enhancing SMAW Training Outcomes: JBLCF-Bacolod’s Journey as TVET Provider

May M. Baylon, MBA

In-Charge, TESDA Program

John B. Lacson Colleges Foundation (Bacolod), Inc. started its TVET journey in 2020. It offered on the same year Shielded Metal Arc Welding (SMAW) NC 1, its very first Technical Vocational Education and Training (TVET) program duly registered under the Technical Education and Skills Development Authority (TESDA),

Innovation support is one of the requirements in all TVET Programs, as indicated in Number Five of the Basic Competencies of TESDA’s 21stCentury Curriculum. The Director General of TESDA, Sec. Suharto T. Mangudadato emphasized during the Technical Institutions' Conference in June 2023 at TESDA’s Main Office in Taguig, Manila, that “TVET Institutions should take the lead in reinventing and restyling their programs, systems, and mechanisms through innovation in technical vocational education and training and Tech-Voc should not just acquiring skills and competencies but rather on improving the economic and social standing of the Filipino workforce."

The mandate of TESDA to support innovation propelled the school’s TESDA Training and Assessment Center to ensure that learning activities and outputs emphasized innovating the processes and materials used in every required project that hones the competencies and skills of trainees. Local Government Units sponsor most of the TechVoc training the department implements, and some are funded by TESDA. As a training under scholarship, it is prohibited to require trainees to spend for their projects or any other reasons related to their training. In order to develop the trainees’ skills and competencies in welding, they gather scrapped and used materials stocked in the school’s Material Recovery Facility (MRF) to convert them into another usable material.

Cutting-edge approaches were employed in re-creating and converting the gathered metal and non-metal scrap. They turned materials into new usable items for the school and the community, including advanced recycling techniques and innovative upcycling methods that reduced waste and facilitated sustainability and resourcefulness among the trainees.

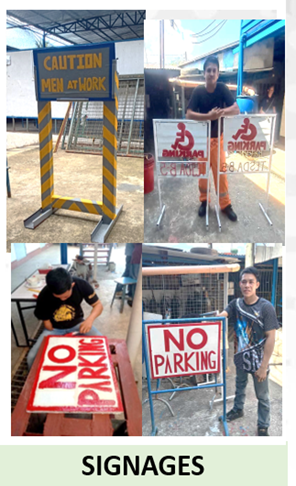

Advanced recycling techniques involve collecting metal and non-metal scrap, discarded and considered waste materials, and are converted into new materials or products. This practice allows SMAW trainees to apply their basic welding skills. Various competencies stipulated in their curriculum are developed through individual and group projects. These include their ability to communicate and build relationships with fellow trainees, adherence to different safety and environmental policies and procedures, and a sense of creativity and aesthetics in creating their projects. The trainees were able to convert these metal and non-metal scrap materials into tables, cabinets, school signages, and cleaning tools.

The innovative upscaling method transforms metal and non-metal waste materials into new items of higher quality or value. Instead of buying new and ready-made tools and equipment required in SMAW NC 1 and 2 programs, the trainees were required to create some of these tools and equipment using metal scrap materials.

The chipping hammers and the tongs are some of the tools used in welding fabricated by SMAW trainees as part of their project. The chipping hammers are tools to remove slags from welds and to clean the weld area, while the tongs are crucial for maintaining safety and precision in welding operations. Likewise, electrode ovens, required welding equipment, are used to maintain the quality and reliability of welding electrodes as a critical process in the integrity and strength of welded joints. The trainees could fabricate 11 units that enable the school to meet the required quantity in its application for SMAW NC II and in its preparation to apply as an assessment center for SMAW NC 1 and SMAW NC 11.

Another upcycling output among trainees is fabricating a functional push cart using discarded C-purlins and other metal scraps. They use this to transfer heavy loads of materials and other items from one place to another within the campus. The school's maintenance personnel also benefit from this project when transferring voluminous and heavy loads.

The use of innovative training approaches by the TESDA Training and Assessment Center is part of its journey to becoming a provider of quality Technical Vocational Education and Training (TVET). It aims to achieve higher passing rates for national certification in Shielded Metal Arc Welding (SMAW) NC 1 and to create environmentally beneficial learning activities. These training initiatives by Mr. Ian Raymond M. Cenidoza, a registered TESDA SMAW Trainer and Assessor, ultimately intend to develop the trainees’ skills and competencies required by the training regulation of the program and, most importantly, make them a competent workforce in the metals and engineering industry sectors worldwide