Integrated Protection Device for Inductive Loads against Power Abnormalities: A Collaborative Innovative Project

Engr. Joel Panganiban

Engr. Ruby Oro

Engr. Ritchie Navarro,

3/E Paul Olimpos

Mr. Rogie Padernal

College of Maritime Education

Introduction

John B. Lacson Colleges Foundation (Bacolod), Inc. faces one major problem: sudden over and under voltage, which damages the institution's equipment, specifically the air conditioners. This problem is common and can create problems for consumer goods and industrial protection.

The institution must create an innovative output to protect and save costs instead of buying new equipment for replacement. Thus, the team aimed to design an integrated protection device for inductive load against power abnormalities. The output of this project will be used on the premises of John B. Lacson Colleges Foundation (Bacolod), Inc. to address the problem.

Objectives

The project's main objective is to develop a miniature protection device for 1HP air conditioners or any equivalent inductive load in case of under and over voltage. Specifically, the innovation aims to:

1. Design an off-the-shelf protection device to monitor the over and under-voltage.

2. Design and test the protection device on the under and over voltage of a 1HP air conditioner or any equivalent inductive load.

3. Develop various controlled parameters to obtain a good performance indicator for the under and over-voltage protection device.

Outline in Developing the Prototype and Simulator

The following are the steps in developing the prototype and simulator of the protection device:

1. Preparing the Objectives

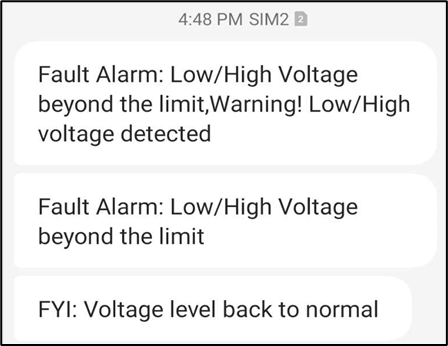

The objective of this device is to simulate the use of under/over voltage protection. An alarm is provided via text messaging to notify the person in charge. A simulator device is set up to obtain a low voltage level, triggering the protection.

2. Sizing of the Electrical Components

The load used here is limited to 1HP window-type air conditioners or any equivalent inductive load. The ratings of switching contacts are based on 747 Watts @ 220 Vac.

3. Designing of the Circuit

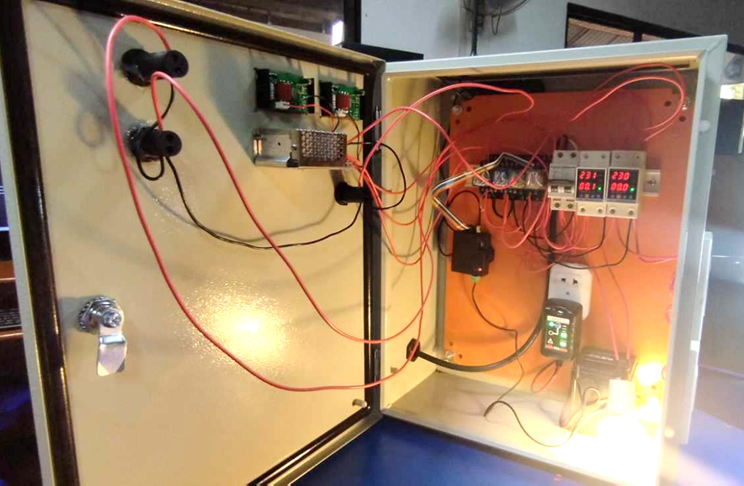

The following are the components of the device: Protection device (the circuit is composed of a circuit breaker, under/over voltage detector, control relays, and indicators) and low voltage simulator (AC variable voltage and regulator). These components are assembled in a control panel, and the wirings are terminated.

4. Calibration, Programming, and Configuration of Devices

The voltage indicated by the panel voltmeter is compared using a portable, calibrated voltmeter. The panel voltmeter is then calibrated by adjusting it with the readings from the calibrated voltmeter.

5. Energize and Perform the Simulation Testing Procedure

The circuit breaker is switched on by flipping it upward. The voltmeter indicates the input and output voltage levels. A 1 HP capacity air conditioner or any electrical appliances is plugged into the socket. The variable voltage knob is adjusted to set for a low voltage level.

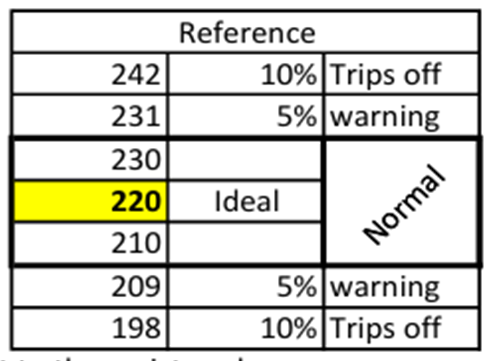

When the voltage reaches 209 V or 231 V, the warning indicator is lit, and a text message is sent to the registered users. When the voltage reaches 198 V or 242 V, the circuit is opened, and a text message is sent to the registered users' phones.

The warning indicator turns off when the voltage returns to normal (210 to 230), the circuit breaker relay is active again, or the circuit is closed.

Evaluation of the Integrated Protection Device

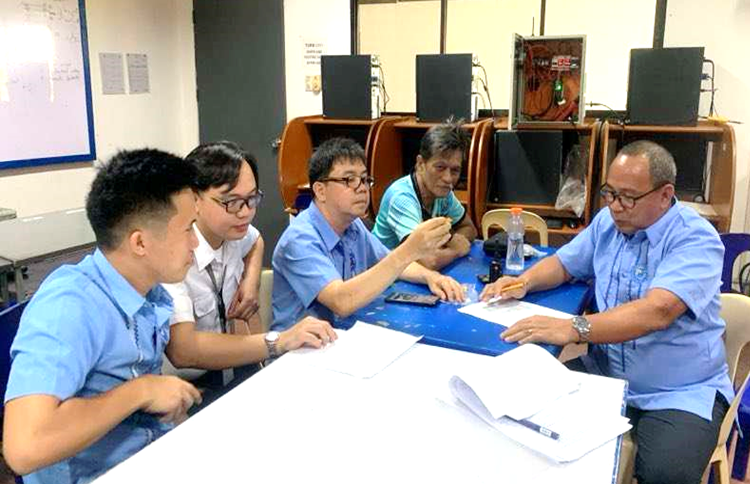

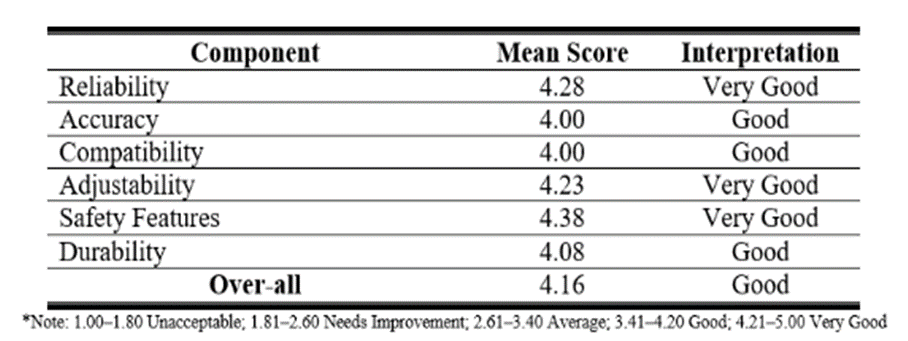

After prototyping the design, trial testing, calibration, and simulation testing, the device was evaluated by the Administrator, Research Coordinator, two electrical Engineers, 1 Mechanical Engineer, and two Marine Engineers. The evaluation tool consisted of the following components: Reliability, Accuracy, Compatibility, Adjustability, Safety Features, and Durability with the following breakdown of scores:

Conclusion

Based on the evaluation results of the Integrated Protection Device for Inductive Loads against Power Abnormalities, it is evident that the device performs exceptionally well across various key metrics. With very good reliability, adjustability, safety features, and good accuracy, compatibility, and durability, it is notable that the device excels in providing reliable and accurate protection while ensuring compatibility and adjustability for different setups. The high safety features and durability further emphasize the robustness and longevity of the device, making it a dependable choice for safeguarding inductive loads against power abnormalities.

The evaluation results highlight the Integrated Protection Device as a top-performing solution for protecting inductive loads against power abnormalities. Its consistently high ratings across reliability, accuracy, compatibility, adjustability, safety features, and durability signify its effectiveness and resilience in maintaining stable and secure operations. Educators and professionals can confidently rely on this device to ensure the safety and longevity of their inductive load systems, knowing that it offers a comprehensive and dependable level of protection against various power-related issues.

Recommendations

The team recommends the following courses of action. First, to reproduce a compact design without the simulator, it is essential to collaborate with the engineering team to streamline the components and ensure that the device maintains functionality in a smaller form. Once this is achieved, the next step would be to move forward with testing on the actual integrated system of the device. This real-world testing will provide valuable insights into the device's performance under practical conditions and allow for any necessary adjustments to be made before full-scale implementation.

Secondly, gathering data on the device's performance over one year is important for assessing its long-term efficacy. By collecting data on factors such as accuracy, durability, and user feedback, the team can identify areas for improvement and refine the device to better meet the needs of its users. Additionally, securing support from the administration to continue the innovation process is vital. This support not only provides the necessary resources for further development but also validates the importance of the project, fostering a culture of innovation within the organization.